IN 1950, THE EAMES PLASTIC CHAIR WAS LAUNCHED ON THE MARKET AS THE FIRST CHAIR WITH A SEAT AND BACKREST FORMED FROM A SINGLE PLASTIC SHELL - A GROUND-BREAKING INNOVATION DEVELOPED BY CHARLES AND RAY EAMES TO MEET THE NEEDS OF A CHANGING SOCIETY.

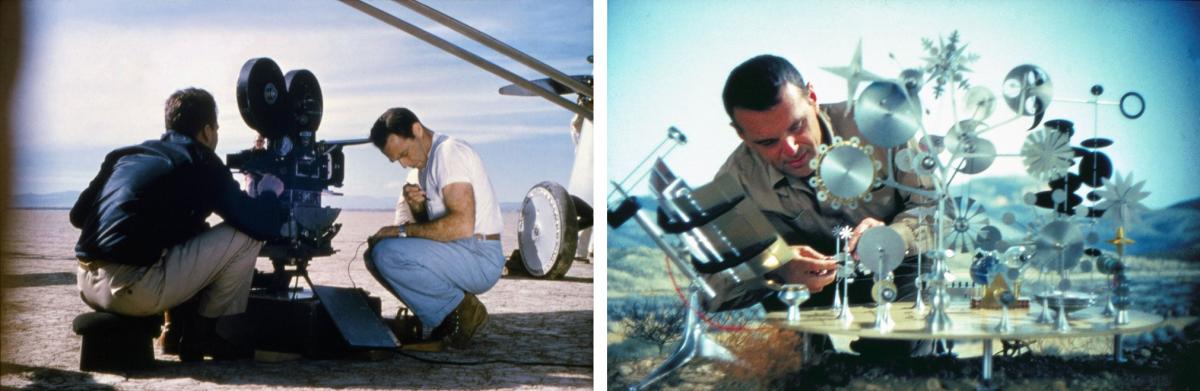

Charles Eames regarded himself first and foremost as a tradesman. He was very interested in technology, and it was therefore natural for him to engage with people or things that he could learn from: consulting material specialists (fibreglass, plywood, aluminium), observing film director Billy Wilder on set (where Eames believed he learned more about architecture than anywhere else), or collecting toys (out of the conviction that toys were preludes to serious ideas). Usually the development of the Eames’ designs was triggered by some real and immediate need – a need of their own, a need expressed by a friend, or a need in connection with a building or situation.

The Eames Plastic Chair was developed in 1948 as part of an entry for the Museum of Modern Art’s "International Competition for Low-Cost Furniture Design", and it is probably the design that best shows Charles and Ray Eames’ desire to get the best to the most for the least. The goal was to mass-produce a chair for the home market with a one-piece seat and back. The first proposal was not made of plastic but had a stamped metal shell – which turned out to be a costly affair – and in their search for a cheaper way to produce the design, the Eames’ attention was soon drawn to fibreglass.

The ultimate result was very straightforward. The chair was meant to be practical, easy to clean, light and robust, and all this became possible with the new material of fibreglass, which had never been used for furniture in this way. The design turned out to be a ground-breaking innovation. The mass-produced armchairs in fibreglass were offered for sale in 1950, and from their first appearance they met with favourable reviews in the press and commercial success in the marketplace.

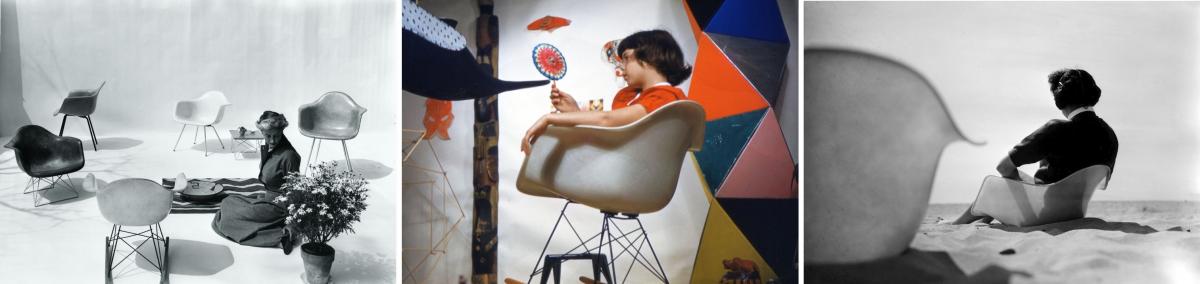

This new design was conceived as a seating group comprising two shells – an armchair and a side chair – in combination with a variety of bases, including a rocker with a rod base on wooden runners, and a four-legged base in tubular steel. The chairs were first available in three subtle colours: ‘greige’ (a combination of grey and beige), elephant-hide grey, and parchment (the natural colour of actual parchment, made in fibreglass with a clear resin and an added touch of grey or black). Later a variety of colours was offered, along with a choice of several more bases: cast aluminium pedestal, swivel, wire, or wood dowel legs – connected to the shell with the rubber shock mounts the Eames had developed in 1946 to give extra resilience to the Plywood Group.

The Eames Plastic Group was first regarded as seating for the home, but within a few years the chair shifted its position in the market and became more popular in public spaces. By this time Charles and Ray Eames had invented a range of new bases, like the beam seating and stacking bases, and had also widened the choice of colours for the shells.

The side chair, in particular, was used extensively in public spaces, and due to its ubiquitous presence, it took on a certain invisibility – being taken for granted by many who used it on a daily basis in restaurants, schools, and office buildings. Thus, this chair was at once highly ‘visible’ in design-conscious circles and yet somewhat ‘invisible’ in the ordinary world.

Over the following four decades, the chair enjoyed great success, and the Eames themselves utilised several different models in their own home, mixing them with the Plywood Group around their dining table and also using them on the outdoor terrace.

During the same period, production technology also changed, and the competition from cheaper chairs grew stronger. The Eames fibreglass chairs, originally intended (and long established) as affordable mass-produced seating, were eventually overtaken by technological advancements, cheaper materials, and more ecological manufacturing methods, leading to the discontinuation of production for a short time in the 1990s.

In close collaboration with the Eames family, the Eames Plastic Group was re-launched in 1998 with shells made of polypropylene, a thermoplastic polymer that satisfied technical demands in regard to strength and resilience. The substitution of polypropylene for fibreglass also made it possible to manufacture the Eames Plastic Group with more affordable and ecological production techniques.

Charles and Ray Eames did not work with the aim of inventing iconic designs. The Eames liked to think that they designed for themselves, but only within the framework of their conviction that they were very much like a lot of other people. They believed that if you design for yourself, then you need to make sure you design deeply for yourself, because otherwise you are just designing for your eccentricities – and that’s where you’re different.

This article has been published in its entirety courtesy of Vitra. To read further articles from Vitra, visit the Vitra Magazine: https://www.vitra.com/magazine.

Copyright for all images: Eames Office LLC, 2017.